The rock crackers

ETH Zurich researchers working at NAGRA's Grimsel rock laboratory have retreated deep inside the mountain. By fracturing solid rock, they are hoping to re-examine the feasibility of geothermal power plants based on petrothermal technology.

It's an icy-cold early December day at the Grimsel Test Site, nestled at the foot of the dam that holds back the Räterichsbodensee reservoir. Water has frozen into bizarrely shaped ice streams on the huge slabs of rock. We take one last glimpse out of the window before the VW minibus plunges into a tunnel leading into the mountain beneath the dam wall.

After driving a good kilometre, the minibus stops next to a niche in the rock. Bicycles are propped against the wall to the right of a greenish-blue steel door. An illuminated sign spells out “Welcome to the NAGRA Rock Laboratory”, marking the entrance to the research facility's centre of operations. It's not as cold here: deep inside the Juchlistock mountain, with 450 metres of solid granite over our heads, the temperature stays at a steady 13 degrees. Engineering geologist Florian Amann covers the last few hundred metres to the laboratory on foot, advancing further down the tunnel that was carved out by the energy supply company Kraftwerke Oberhasli AG when it built the hydroelectric power plant.

Amann swings open a metal door and heads down a concrete staircase that leads to a large cavern. A researcher is crouched on the floor staring transfixed at his laptop, which is propped up in front of him on a chair. One of his colleagues in bright yellow work trousers is monitoring a dozen pressure sensors, and a tangle of green hoses is lashed to a rack on the wall. No daylight enters the cavern, and apart from the murmurs of the scientists there's not a sound to be heard.

This underground cavern is the setting for a one-of-a-kind experiment that aims to pave the way for deep geothermal energy in Switzerland: the In-situ Stimulation and Circulation experiment, known for short as ISC.

The scientists working on this experiment are hoping to discover how to crack solid rock in order to create and maintain an efficient heat exchanger – a key component in producing electricity in geothermal power plants.

To fracture solid rock, researchers “stimulate” it by pumping water into boreholes under high pressure. This causes the rock to rupture, after which water can be heated up by pumping it through the resulting system of cracks. The researchers hope to discover whether this system of cracks can be maintained over a longer period of time and whether the water circulation is sufficient to make operation of the heat exchanger economically viable.

The experiment is also designed to show, which method of fracturing rock is the most practical. Rock can be fractured in two different ways, and the scientists here are using both. The first method is hydraulic fracturing, where the scientists steadily increase the water pressure in a borehole until the solid rock cracks. The second method is hydraulic shearing, where the geoengineers apply targeted increases in water pressure to existing cracks in the rock. That causes the crack walls to dislocate, making the cracks bigger.

Political pressure

The scientists are particularly keen to find ways of minimising the number and intensity of earthquakes that occur during stimulation. This issue was one of the key reasons behind the failure of the deep geothermal energy projects in Basel and St. Gallen. At both sites, local inhabitants felt the earthquakes that were triggered when the bedrock was pressurised. Both projects were terminated, marking a setback for geothermal energy.

“Current experience of petrothermal systems amassed around the world indicates that there is a way do this without causing detectable earthquakes,” says Amann, “and that's what we want to achieve, too.” The researchers have also been spurred on by recent political events: in its Energy Strategy 2050, the Swiss Federal Council included the goal of using geothermal power plants to generate 7 percent of Switzerland's energy requirements, amounting to 4.4 terawatt hours, or one and a half times the output of the Beznau I nuclear power plant. To achieve this goal, a total of 25 geothermal power plants, each generating 20 megawatts, will need to be commissioned over the next 30 years.

Two years of preparation

Amann and his team have spent two years carefully preparing every last aspect of the experiment. Everything has to be in place the day he finally presses the “red button”: “We only get one shot at cracking the rock,” says the engineering geologist, noting that the rock can't be patched up again once it's been fractured. “If something goes wrong, we would have to develop a whole new fresh body of rock, and we simply don't have the time or the money for that.”

To prepare the experiment, the researchers conducted a detailed analysis of the rock at the test site to familiarise themselves with every last centimetre of the rocky mass. That puts them in a position to compare the condition of the rock before and after the water is injected.

They also drilled 15 boreholes into the rock ranging from 18 to 50 metres deep and up to 15 centimetres in diameter and equipped these with highly sensitive measuring instruments.

The researchers need three of the boreholes to conduct strain and temperature measurements, four for seismic measurements, and four for pressure and strain monitoring. They need to capture every last detail of any dislocation, deformation or change of pressure in the rock. Highly sensitive micro seismometers are also positioned outside the boreholes to record any vibrations that occur before, during and after the water stimulation.

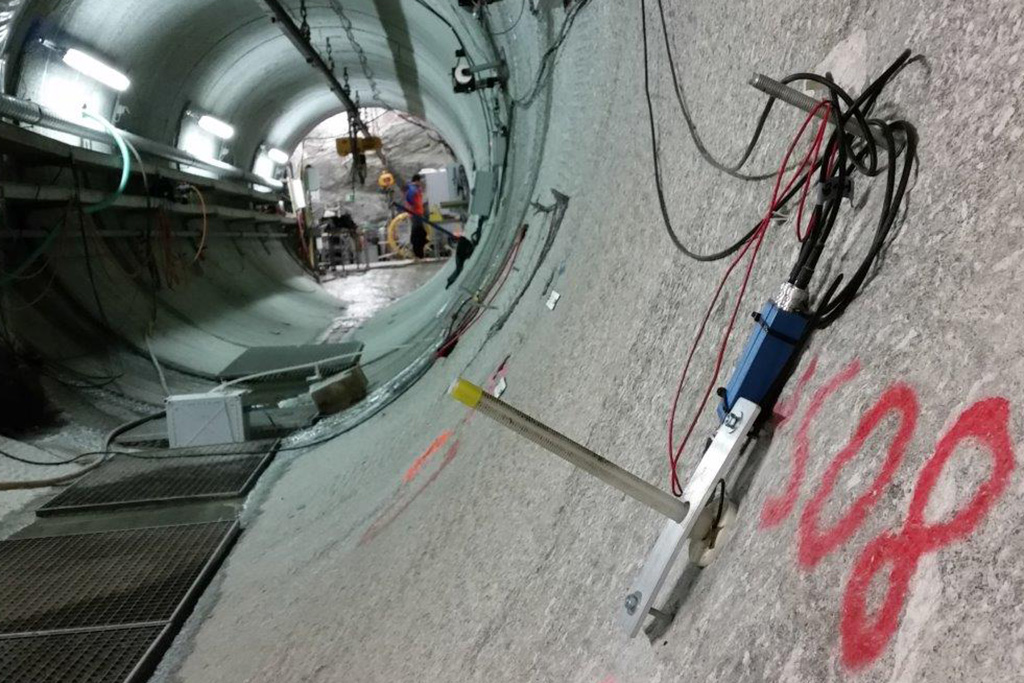

Amann leaves the cavern and enters a circular tunnel drilled by a tunnel boring machine. Cables run along the walls and water from the rock trickles along the floor. After 30 metres, he stops in front of an inconspicuous little box mounted on the rocky floor of the tunnel. He stoops down to briefly check that it's intact. “This is a tiltmeter,” he explains, “which measures the inclination of the granite tunnel floor to detect any deformation caused by changes in the rock.” The tiltmeter can even detect the tiny inclination of the floor that occurs when somebody walks past the sensor. “Once we start the experiment nobody will be able to walk around down here,” emphasises the project manager, “as this would distort the readings and we would have to remove that interference from the data afterwards.”

Real-time modelling

Data is central to this experiment, and so is data management. Seismic monitoring alone generates terabytes of data. The researchers have continuous access to this data from ETH Zurich thanks to the cavern's direct internet connection.

“A lot of computing power comes into play during stimulation,” says Amann. The data is transmitted in real time to enable a simulation to instantly predict the next few minutes of the experiment.

Analysing all the data will take two to three years. “We're producing enough data for generations of doctoral students,” notes the project manager. A full overview of the ISC experiment is not due to be completed until 2020, though industrial partners won't have to wait that long for the key findings. “Industry is very interested in our results. We'll be providing them with valuable data from an early stage,” Amann says.

Nonetheless, the researchers (and the electricity industry) are still very much at the start of a long journey. The ISC experiment is “only” a pilot project and is on a much smaller scale than a “proper” geothermal power plant. So why bother with this kind of experiment? “The method we're using to crack the rock can't be tested in a borehole that's 5,000 metres deep,” says Amann. As well as the prohibitive costs this would entail, it would also be virtually impossible to equip such a deep geothermal borehole with this type of sophisticated measuring equipment. That's why the researchers have to reproduce this kind of system on a small scale and then use a computer model to scale it up. “The work we're doing here is a key part of minimising and perhaps even eliminating the risks posed by this technology,” Amann adds.

ISC experiment

The ISC experiment falls under the remit of the Swiss Competence Center for Energy Research – Supply of Electricity (SCCER-SoE). It involves six professors from ETH Zurich and one from the University of Neuchâtel. The experiment is led by Florian Amann from SCCER-SoE. The ISC experiment is funded by the Swiss National Science Foundation, the Swiss Federal Office of Energy, and industrial partners including Shell and EKZ.

Convinced of its feasibility

Time underground passes at a sluggish pace. The fluorescent lights cast a steady glow that gives no clue as to how much of the day has already passed. Occasionally the sound of an engine penetrates as far as the cavern. The men's stomachs start to rumble. It's midday, time to get a bite to eat with the other researchers back at the rock laboratory's centre of operations.

Amann heads up the stairs, followed by his colleagues. He opens the greenish-blue steel door, enters the dimly lit main tunnel and makes his way back to the main offices on foot.

Originally the researchers had wanted to fracture the rock in early December, but problems with the delivery of certain measuring instruments upset their plans. Amann doesn't see that as a bad omen, though. He is confident that the experiment will generate valuable data and mark an important step forward for deep geothermal energy.

His faith in this method of power generation is equally unshakeable: “I'm convinced that geothermal power plants will meet some of our energy needs in the future. And what we're doing here will provide the basis for Switzerland to exploit this low-CO2 energy source.”

This article appeared in issue 1/2017 of the ETH magazine Globe.

Text and images: Peter Rüegg